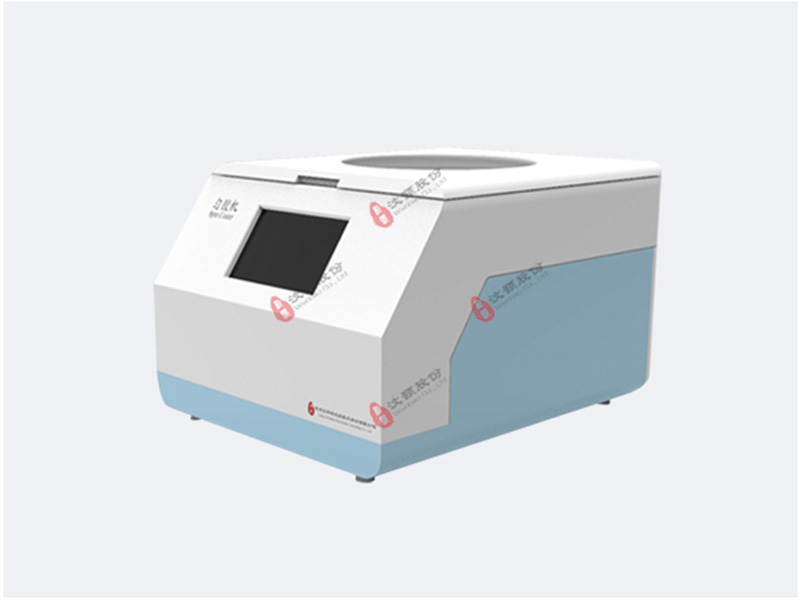

A spin coater is a gadget used to apply a film to a substrate. The spin coating machine will pivot a substrate at different paces while covering material is administered onto its surface.

The spin coater is gone on while the liquid veers off the edges of the substrate, until the ideal thickness of the film is accomplished.Turn coaters are utilized during the time spent on spin coating machine.

Turn covering includes the use of a slender film (a couple of nm to a couple um) equitably across the outer layer of a substrate by covering (projecting) an answer of the ideal material in a dissolvable (an “ink”) while it is pivoting. Set forth plainly, a fluid arrangement is stored by spin coater manufacturer and spin coater supplier onto a turning substrate to deliver a slim film of strong material, like a polymer.

A spin coater implies that the centripetal power joined with the surface strain of the arrangement maneuvers the fluid covering into an in any event, covering. During this time the dissolvable spin coater then dissipates to leave the ideal material on the substrate in an in any event, covering.

In the underlying advance, the arrangement of spin coater manufacturer and spin coater supplier is projected onto the substrate, normally utilizing a pipette. Regardless of whether the substrate is now turning (dynamic twist covering) or is turned after affidavit (static twist covering), the diffusive movement will spread the arrangement across the substrate.

The substrate then, at that point, spin coater manufacturer and spin coater supplier arrives at the ideal revolution speed – either right away or following a lower-speed spreading step. At this stage, the majority of the arrangement is removed from the substrate.

At first, the liquid might be turning at an unexpected rate in comparison to the substrate, yet at last the revolution paces between spin coater manufacturer and spin coater supplier will coordinate when drag adjusts rotational speed increases – prompting the liquid becoming level.

The liquid presently starts to thin, as it is overwhelmed by thick powers. As the liquid is flung off, regularly the spin coater will change tone because of impedance impacts (see video beneath). At the point when the shading quits changing, this will show that the spin coater is generally dry. Edge impacts are here and there seen in light of the fact that the liquid should frame drops at the edge to be distracted.

At long last, spin coater outpouring stops and diminishing is overwhelmed by vanishing of the dissolvable. The pace of dissolvable vanishing will depend on the dissolvable instability, fume pressure, and encompassing circumstances. Inconsistencies in vanishing rate, such at the edge of a substrate, will cause comparing non-consistencies in the spin coater.

FAQ

4 main steps of using a spin coating machine?

Stage One: The primary stage of using a spin coating machine is the affidavit of the covering liquid onto the wafer or substrate.

Spin coating machine very well may be finished utilizing a spout that spills the covering arrangement out, or spin coating machine is very well may be showered onto the surface, and so on Normally this administer stage gives a significant overabundance of covering arrangement contrasted with the sum that will eventually be expected in the last covering thickness.

For some arrangements of spin coater manufacturer and spin coater supplier it is frequently advantageous to apportion through a sub micron measured channel to take out particles that could prompt imperfections. Another possibly significant issue is whether the arrangement wets the surface totally during this apportion stage. On the off chance that not, then, at that point, deficient inclusion can result.

Stage Two: The subsequent stage is the point at which the spin coating machine is sped up to its conclusive, wanted, pivot speed.

This stage is typically portrayed by forceful liquid ejection from the spin coating machine surface by the rotational movement. On account of the underlying profundity of liquid on the spin coating machine surface, winding vortices may momentarily be available during this stage.

These would frame because of the bending movement brought about by the idleness that the highest point of the liquid layer applies while the spin coating machine underneath turns quicker and quicker. In the end, the liquid is adequately slender to be totally co-turning with the wafer and any proof of liquid thickness contrasts is no more. At last, the spin coater arrives at its ideal speed and the liquid is slender enough that the gooey shear drag precisely balances the rotational speed increases.

Stage Three: The third stage is the point at which the lab spin coater is turning at a consistent rate and lab spin coater powers rule liquid diminishing conduct.

This stage is portrayed by slow liquid diminishing. Liquid diminishing is for the most part on lab spin coater.

however with arrangements containing unstable solvents, it isn’t unexpected to see impedance tones “veering off”, and doing as such logically more leisurely as the covering thickness is decreased. Edge impacts are regularly seen in light of the fact that the spin coater streams consistently outward, yet should shape beads at the edge to be flung off.

Along these lines, contingent upon the surface strain, consistency, turn rate, and so on, there might be a little dot of covering thickness distinction around the edge of the last spin coater. Numerical medicines of the stream conduct show that if the fluid displays Newtonian consistency (for example is straight) and in the event that the liquid thickness is at first uniform across the spin coater, then, at that point, the liquid thickness profile at any after time will likewise be uniform – – – prompting a uniform last covering (under ideal conditions).

Stage Four: The fourth stage is the point at which the lab spin coater is turning at a consistent rate and dissolvable lab spin coater rules the covering diminishing conduct.

As the earlier stage progresses, the liquid thickness arrives where the consistency impacts yield just a rather minor net liquid stream. Now, the vanishing of any unpredictable dissolvable lab spin coater will turn into the prevailing system happening in the covering. Truth be told, now the covering successfully “gels” on the grounds that as these lab spin coaters are eliminated the thickness of the leftover arrangement will probably rise – – really freezing the covering set up.

This conduct was utilized in the fundamental work of lab spin coater where he evaluated the covering thickness, reliance on turn speed and consistency and its relationship to the dissipation rate.

In the wake of turning is halted numerous lab spin coater applications expect that heat treatment or “terminating” of the covering be proceeded. Then again, lab spin coater for the most part go through different cycles, contingent upon the ideal application/use.

Obviously arranges 3 and 4 depict two cycles that should happen at the same time over the course of all times (gooey stream and vanishing). Notwithstanding, at a designing level the thick stream impacts overwhelm right off the bat while the vanishing processes rule later.

Spin coater applications?

Spin coating is incredibly broadly utilized by spin coater manufacturer and spin coater supplier and has a deferred scope of utilizations. The method can be utilized to cover anything from little substrates estimating a couple of millimeters squared, up to level board shows which may be a meter or more in distance across.

It is utilized by spin coater manufacturer and spin coater supplier for covering substrates with everything from photoresistors, protectors, natural semiconductors, engineered metals, nanomaterials, metal and metal oxide antecedents, straightforward conductive oxides and a lot more materials. So, turn covering is omnipresent all through the semiconductor and nanotechnology R&D and modern areas.

It has been utilized by spin coater manufacturer and spin coater supplier for a very long time for the utilization of slim movies. In this interaction, a little drop of the covering material is stacked onto the focal point of a substrate, which is then turned at a controlled rapid.

In the twist covering process, the spin coater china company twirls around a hub which should be opposite to the covering region. Therefore, the covering material spreads towards, and in the end off, the edge of the substrate leaving a slender film of covering on a superficial level. Last film thickness and spin coater china company will rely upon the idea of the covering (consistency, drying rate, percent solids, surface strain, and so on) and the boundaries picked for the twist cycle, for example, the turn speed.

Benefits of Spin Coating?

The fundamental benefits of spin coating are:

- The effortlessness and relative straightforwardness with which an interaction can be set up combined with the spin coater china company and uniform covering that can be accomplished at different thicknesses makes it ideal for both research and quick prototyping of spin coater china company.

2.The capacity to have high twist speeds prompts quick drying times (because of the great wind current) which thus brings about high consistency at both perceptible and nano length scales for spin coater china company, and frequently eliminates the spin coater china company’s requirement for post-disposition heat treatment.

3.Spin coating is an exceptionally minimal expense method for clumping process individual substrates contrasted with different strategies implemented by spin coater china company, large numbers of which require both more costly gear and high energy processes.

The quick drying times spin coater china company can likewise prompt lower execution for some specific nano-innovations (little atom OFETs for instance) which expect time to self-collect as well as solidify. In spite of these downsides, spin coating is generally the beginning stage and benchmark for most intellectual and modern cycles that require a spin coater china company and uniform covering.