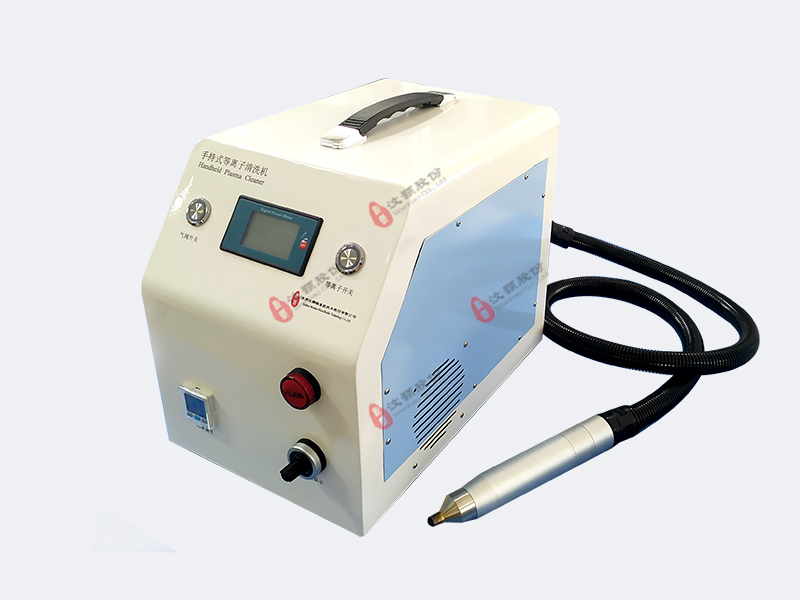

plasma cleaner

Plasma surface treatment is a cycle that plasma cleaner manufacturer raise the surface energy of numerous materials in order to further develop the holding qualities. One type of plasma treatment is likewise generally known as a crown treatment, which was designed by Danish plasma cleaner manufacturer Verner Eisby during the 1950s. As a rule this cycle is the standard treatment for materials, for example, plastic polymers, papers, movies, glass, and even metals.

plasma treatment machine is a comprehensive instrument for a wide range of purposes for surface treatment, for example, cleaning, covering, printing, painting, and cement holding.plasma treatment machine has come to incorporate such countless various applications that it is presently one of the top techniques in surface treatment, particularly in ventures which depend vigorously on bundling.

There are various modern and bundling arrangements made constantly because of the wide adaptability wherein plasma treatment machine can be applied. This innovation is even vigorously utilized in the car and airplane businesses. Plasma treatment machine additionally yield exceptionally excellent items in essentially every relevant field while being harmless to the ecosystem cycle.

A plasma treatment machine is considered as the fourth condition of issue. It is a novel handling medium with regards to treating surfaces and for surface alterations. plasma treatment machine is an ionized gas that comprises particles, electrons and impartial molecules.

While electrons in the plasma treatment machine exist at a higher temperature when contrasted with unbiased gas, the plasma treatment machine is consistently at close encompassing temperature with the thickness of its electron being around 1010 cm-3.

Plasma cleaner cleaning has the ability to successfully eliminate all natural defilements from surfaces through the course of a synthetic response (air plasma) or actual removal (Ar plasma/Argon plasma).

A plasma cleaner likewise works with substance utilitarian gatherings, for example, carboxyl, carbonyl and hydroxyl on a superficial level, which brings about delivering most surfaces hydrophilic. Aside from being spotless, a plasma cleaner likewise must be hydrophilic, for example having a diminished measure of water contact point with an increment in wettability to upgrade the holding or attachment to different surfaces during the assembling system.

Aside from that, Plasma cleaner cleaning has the ability to successfully eliminate all natural defilements from surfaces through the course of a synthetic response (air plasma) or actual removal (Ar plasma/Argon plasma).

A plasma cleaner likewise works with substance utilitarian gatherings, for example, carboxyl, carbonyl and hydroxyl on a superficial level, which brings about delivering most surfaces hydrophilic. Aside from being spotless, a plasma cleaner likewise must be hydrophilic.

For example, having a diminished measure of water contact point with an increment in wettability to upgrade the holding or attachment to different surfaces during the assembling plasma cleaner system, is additionally used to eliminate microbial toxins from a plasma cleaner , which makes it very useful for disinfection in biomaterials research applications.

Plasma cleaner eliminates natural pollutants by synthetic response (O2 or air plasma) or actual removal (Ar plasma). Plasma cleaner likewise presents different compound useful gatherings (hydroxyl, carbonyl, carboxyl, amine) on material surfaces, subject to the cycle gas.

Plasma cleaner delivers most surfaces hydrophilic, which can be seen as a decline in water contact point and expanded wettability. A perfect and hydrophilic surface is regularly basic to elevate attachment and to upgrade holding with different surfaces.

FAQ

Why do we use plasma treatment machine?

plasma treatment machine is expected for the expulsion of impurities from surfaces before they can be utilized in the assembling system.

plasma treatment machine can be applied to a variety of materials alongside surfaces with complex calculations.

A plasma treatment machine framework permits the productive cleaning of a surface without contrarily affecting different properties of the surface.

Throughout the course of recent years, the proficiency of plasma treatment machine has been perceived, and utilized for an assortment of pre-handling cleaning of materials.

Coming up next will be some data on what plasma treatment machine truly and it’s utilized for

What are the applications of Plasma surface treatment machine?

Plasma surface treatment machine frameworks can be utilized for an assortment of surface cleaning purposes prior to handling. Plasma surface treatment machine is productive for eliminating surface oxidation and cleaning mineral buildup off of surfaces.

Plasma surface treatment machine is additionally utilized for planning surfaces of plastics and elastomers, as well concerning cleaning pottery. Plasma surface treatment machine is likewise utilized for cleaning the outer layer of glass, as well as metal surfaces.

Utilizing effectivePlasma surface treatment machine frameworks takes out the requirement for utilizing substance solvents.One significant advantage of utilizing Plasma surface treatment machine is that the whole interaction is administrator amicable and harmless to the ecosystem.

Aside from that, the functional expense of utilizing Plasma surface treatment machine frameworks are low, while giving the best in cleaning surfaces. One more advantage of utilizing a Plasma surface treatment machine framework is that it dispenses with the need to utilize synthetic solvents.

Therefore, plasma cleaner manufacturer utilizes plasma cleaner takes out the requirement for storerooms or for making courses of action for dissolvable garbage removal. Plasma is a demonstrated and powerful strategy for basic surface readiness.

What is oxygen plasma cleaning?

Plasma cleaner manufacturer alludes to any plasma cleaning process where oxygen is likewise utilized in the plasma chamber. Oxygen is likewise utilized in cleaning processes that plasma cleaner manufacturer are done prior to holding. Oxygen can be joined with other gasses too to scratch a surface.

It wouldn’t be inappropriate to say that oxygen is the most well-known gas that is utilized in plasma cleaning. This is predominantly because of its wide accessibility and minimal expense. Oxygen plasma can be made by utilizing an oxygen source on a plasma cleaner manufacturer’s framework.

Moreover, all frameworks that are accessible for plasma cleaner manufacturer scratching can work with oxygen, since it is usually used to clean non-metal surfaces like glass, Teflon and plastics, and furthermore expands the non-metallic surface’s wettability.

How much plasma cleaning costs?

The expense of plasma cleaning hardware is somewhat modest when contrasted with different sorts of material surface cleaning frameworks. Aside from that, the costs that go into the hardware’s yearly support is additionally insignificant, which is the reason the fame of plasma cleaner manufacturer has developed fundamentally throughout the long term.

Plasma cleaning is viewed as a viable and simple-to-utilize technique to accomplish better cleaning results over regular cleaning processes.

Plasma cleaning should be applied anywhere a perfect and dependable surface is required. Plasma cleaning is just difficult and safe. It is likewise harmless to the ecosystem, and undeniably more successful when contrasted with customary wet synthetic cleaning techniques.