Brief introduction of WH-CF-15 double emulsion clamp

The double emulsion fixture produced by Wenhao Co., Ltd. is a fast and reliable connection of two standard microfluidic chips with different hydrophobicity. It can control the preparation of uniform and monodisperse double emulsions, such as single-core and double core double emulsions, the success rate of preparation is above 90%. The fixture system avoids the complicated local modification process of preparing double emulsions by a single-chip system, and the lifetime of hydrophobic modification is more than 30 days.

The double emulsion clamp can match with a series of standard chips by changing the screw length. The standard chip is 4.0 mm in thickness, 15.0 mm in width, and 15.0 to 120.0 mm in length. Customers can order standard or custom chips to be used with jigs to complete a series of multi-core double droplet formation and other uses. In addition, customers can customize according to the requirements of the multi-chip fixture.

Click to download the Patent > >

Advantages of WH-CF-15 double emulsion clamp

Small size, lightweight, strong portability;

Strong chemical stability and corrosion resistance;

3. Use with small size chip, low cost;

4. Wide temperature and pressure tolerance;

5. Small dead volume;

6. It can extend to more than three chips to prepare multiple emulsions

7.It can combine with an optical detection system for easy observation and experiment.

SPEC

| Name | Spec |

| Liquid Inlet | 4pcs |

| Liquid Outlet | 4pcs |

| Thickness of the chip | 4.0mm |

| Width of the chip | 15.0mm |

| Length of the chip | 15.0mm-120.0mm |

| Connecting pipe dimensions | OD 1.6mm |

| Connecting pipe material | PTFE |

| Flow tolerance range | 0-0.25m/s |

| Pressure tolerance range | 30.0bar |

| Temperature tolerance range | -15.0-150.0℃ |

| Dead volume | <0.3μL Every tube |

Standard Components

| Components | Item NO | qty |

| Complete fixture | CF-15-01 | 1set |

| Spring Mat | CF-15-02 | 8pcs |

| M3 Screw | CF-15-03 | 8pcs |

| M3 Nuts | CF-15-04 | 8pcs |

| M3 Long Screw (optional) | CF-15-05 | 2pcs |

| M3Matching nut with long screw | CF-15-06 | 4pcs |

| PTFE tube(Φ1.6*0.6) | CF-15-07 | 5m |

| Hex wrench | CF-15-08 | 1pcs |

Assembly process

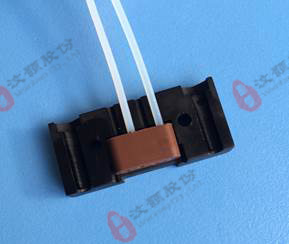

Assembly materials

- Assembly steps

1) insert the sample inlet of the corresponding chip of the PTFE tube into the spring pad, the PTFE tube head is about 1mm from the spring pad outlet, and then place the spring pad with the inserted tube on the corresponding position of the lower cover plate;

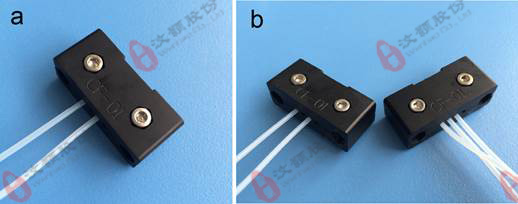

2) the position of the upper and lower cover plates is adjusted well, and the upper and lower cover plates are fixed by screws (a). The assembly of the upper and lower cover plates is completed as shown in b;

3) insert a spring insert into the PTFE (the length of the short tube is the same as the spring insert), insert it into the middle part of the fixture, and place it approximately in the middle.

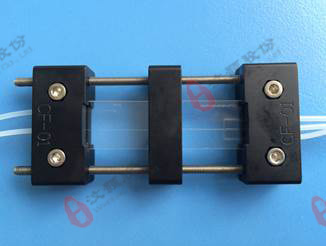

4) assemble two locating screws on the side, connect the above three parts in order. The standard chip is placed in the corresponding position of the fixture, and the adjusting screw is used to fix the chip.

5) use the hexagon wrench to tighten the four screws of the lower cover plate, adjust the chip’s position, and use the hexagon wrench to tighten the two side positioning screws.

Points to note:

1) when using the hexagon wrench to screw the screw, the two sides are alternately tightened slowly to prevent the chip from being broken;

2) test whether the fixture is leaking before the experiment. If it is leaking, adjust the position of the chip and continue to tighten the side screw alternately until no water leaks

- when the chip is finished, please loosen the side screw to prevent the chip from peeling off due to long-term stress.