1. Product introduction of PDMS batch injection molding machine

PDMS chips have become the best material for industrialized chips in many biochemical testing fields due to their air permeability, soft texture, smooth pipes, and short processing cycle. Wen Hao independently developed the semi-automatic and automatic batch injection molding process of PDMS chips. This realizes the semi-automatic and complete automation of the whole process: mixing-dispensing-defoaming-curing-cutting-punching-bonding, which can satisfy customers’ demands for mass production of PDMS chips.

Semi-automatic mass production:

Via the semi-automatic injection molding process of the PDMS chip, the production capacity is 100-400 molds/8 hours. The single-day chip production can reach 2,000 pieces. The annual output is 720,000 pieces.

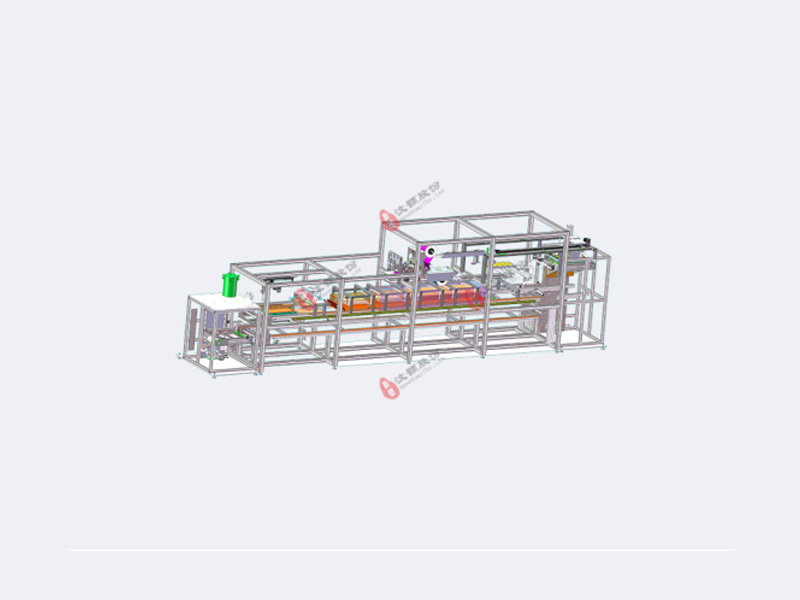

Full-automatic mass production:

Via fully automatic injection molding process of the PDMS chip, the production capacity is 400-2000 molds/8 hours. The single-day chip processing capacity can reach 10,000 pieces, and the annual output is 3 million pieces.

2. PDMS curing machine

3, PDMS dispenser

4. Product features of PDMS batch injection molding machine:

The mixing part adopts a unique stainless steel barrel, vacuum mixing, to ensure that no bubbles are generated after mixing.

It’s a precise automatic digital control intelligent dripping machine, using the latest digital control system to ensure consistent timing and quantitative spitting. The function is more user-friendly, the operation is more straightforward, it can be easily coated, scribed, and dripped, producing high-quality products, improving production efficiency, and saving material costs.

High-precision automatic control system, the accuracy can reach 0.01%

The machine has a smooth delivery system, which ensures the smooth delivery of PDMS.

Constant temperature control system to improve the efficiency of PDMS thermosetting

5.parameter specifications of PDMS batch injection molding machine

| Specification | WHP-100A(vacuum mixing and dispensing part) |

| size | 500×500×466(length×width×height)mm |

| weight | 15Kg |

| Input power | 220 V/50 Hz |

| Input air pressure | 0~0.8mpa |

| Output power | 100 W |

| Digital timer range | 0S~99.99 S |

| Specification | WHP-100A(Thermoset part) |

| size | 1480×708×1500(length×width×height)mm |

| Weight | 约150Kg |

| Max weight capacity | 50KG |

| Input power | 220 V/50 Hz |

| Output power | 1200 W |

| PDMS Thermosetting time(reference) | 15min |

| Temperature control range | Room temperature~160℃(Thermostat control) |