Fabrication of the 3D BAC-eye

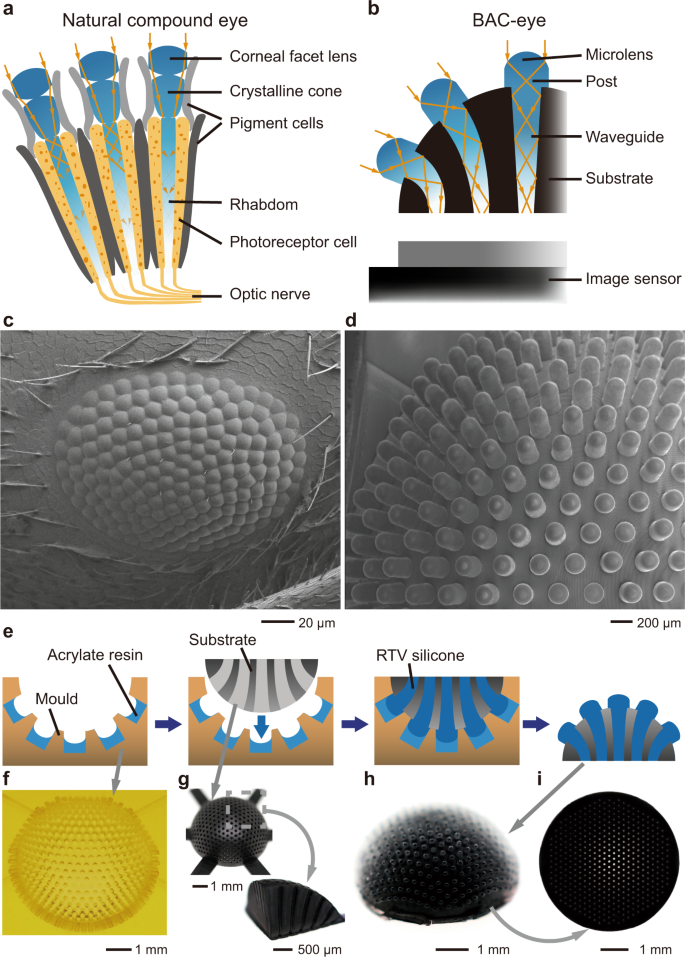

The design of the 3D BAC-eye follows the anatomical structure of an apposition compound eye (Fig. 1a). Each microlens on the BAC-eye has the same function as the corneal facet lens of a natural eye. The cylindrical post and the silicone-elastomer waveguide function as a crystalline cone and a rhabdom, respectively (Fig. 1b). The internal structure of the artificial eye mimics the function of pigment cells to reduce optical crosstalk. The number of ommatidia in the BAC-eye (522) is comparable with that of bark beetles (Dendroctonus rufipennis, average count: 272; Dendroctonus valens, average count: 372), ants (Temnothorax albipennis, average count: 300 (male) and 171 (queens); Brachyponera chinensis, average count: 168 (worker) (Fig. 1c)), and fruit flies (Drosophila melanogaster, average count: 730)47,48,49. Figure 1d shows a top-view SEM image of the BAC-eye. It has a radius of 2.5 mm and its microlenses are hexagonally and omnidirectionally distributed across the hemispherical dome. The most peripheral ommatidia are oriented at ±85° with respect to the vertical axis, extending the viewing angle of the BAC-eye to 170°.

a Anatomical structure of an arthropod compound eye. b Labelled cross section of a BAC-eye. c SEM image of a compound eye of the Asian needle ant, Brachyponera chinensis. d SEM image of a BAC-eye. e Illustration of the main steps of the fabrication procedure. The BAC-eye is produced in a hemispherical substrate by casting it in a prepared mould. f Image of the 3D-printed mould. g The 3D-printed substrate and a quarter sectional slice of the substrate. h Image of a BAC-eye after release from the mould. i A view showing the flat bottom of the BAC-eye.