The photosensitive glass is produced by the continuous melting method with advanced photosensitivity and homogeneity. The glass is a technologically light-sensitive glass. After UV exposure and heat treatment, the photosensitive glass will crystallize. The fine structure with a high aspect ratio and hole can be formed in these crystallization areas after acid corrosion. After the second exposure and heat treatment, the glass matrix can be transformed into glass-ceramics to enhance the mechanical properties of the glass. These properties have led to the widespread use of photosensitive glass in Microfluidics, radio frequency (RF) components, and microelectromechanical systems.

Standard supply sizes for bright glass wafers include wafers 6 inches in diameter or 8 inches in diameter with a 200 x 200 mm square substrate and product thickness of 0.5 mm to 1 mm. In addition, they can be customized according to customer needs of different sizes of glass.

Photosensitive glass has some excellent properties, such as

- A depth to width ratio greater than 10:1;

- Through holes of a minimum diameter of 35 microns (glass of 0.5 mm thickness) ;

3.Minimum spacing of 45 microns;

- Corrosion rate greater than 30:1(treatment and non-treatment) ;

5.Verticality greater than 88 degrees;

- The roughness of the processing area is less than 3 microns

- High-quality uniformity: advanced melting process ensures uniform photosensitivity and high reproducibility;

- Microfabrication without photoresist;

- Excellent light transmission (both visible and non-visible) ;

- Biological compatibility: Temperature Resistance, chemical stability;

- Environmentally friendly: compliant with EU-RoHS and EU-REACH regulations;

12. Photosensitive glass cutting and bonding basically can follow the traditional means of processing.

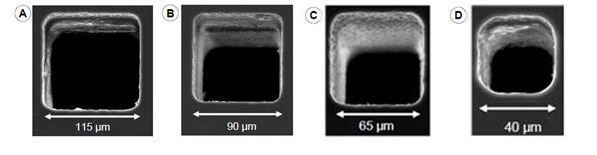

Processing result of the square hole of different sizes of photosensitive glass

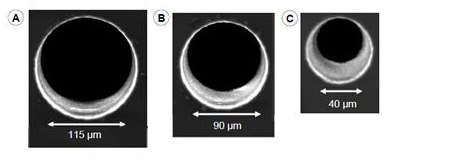

Processing results of circular holes in different sizes of photosensitive glass

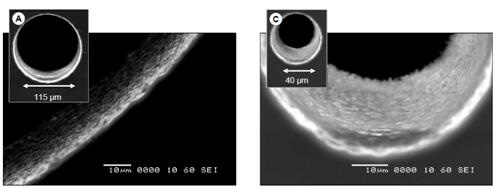

The complex structure of photosensitive glass processing

| Name | Spec | Thickness | Name | Spec | Thickness | |

| Light-sensitive glass | 6 inches | 0.5mm | Light-sensitive glass | Square 93*93mm | 1.0mm | |

| Light-sensitive glass | 6 inches | 0.7mm | Light-sensitive glass | Square 93*93mm | 1.3mm | |

| Light-sensitive glass | 6 inches | 1.0mm | Light-sensitive glass | Square 130*130mm | 0.5mm | |

| Light-sensitive glass | 6 inches | 1.3mm | Light-sensitive glass | Square 130*130mm | 0.7mm | |

| Light-sensitive glass | 8inches | 0.5mm | Light-sensitive | Square 130*130mm | 1.0mm | |

| Light-sensitive glass | 8inches | 0.7mm | Light-sensitive | Square 130*130mm | 1.3mm | |

| Light-sensitive glass | 8inches | 1.0mm | Light-sensitive | Square 150*150mm | 0.5mm | |

| Light-sensitive glass | 8inches | 1.3mm | Light-sensitive | Square 150*150mm | 0.7mm | |

| Light-sensitive glass | 12inches | 0.5mm | Light-sensitive | Square 150*150mm | 1.0mm | |

| Light-sensitive glass | 12inches | 0.7mm | Light-sensitive | Square 150*150mm | 1.3mm | |

| Light-sensitive glass | 12inches | 1.0mm | Light-sensitive | Square 175*175mm | 0.5mm | |

| Light-sensitive glass | 12inches | 1.3mm | Light-sensitive | Square 175*175mm | 0.7mm | |

| Light-sensitive glass | Square 93*93mm | 0.5mm | Light-sensitive | Square 175*175mm | 1.0mm | |

| Light-sensitive glass | Square 93*93mm | 0.7mm | Light-sensitive | Square 175*175mm | 1.3mm |

Above is standard size; non-standard size can be customized, thickness 0.5/0.7/1.0/1.3mm, and customized shape.